Resumen de especificaciones

-

Tiempo de respuesta

t50 = 2,5 s

t90 = 9,5 s -

Máx. presión de proceso (estática)

a 20 °C: 40 bar (580 psi)

-

Rango de temperatura de operación

PT 100:

–40 °C … 160 °C

(–40 °F … 320 °F) -

Máx. longitud de inmersión bajo demanda

hasta 900,00 mm (35,4")

Ámbito de aplicación

La galardonada sonda de temperatura inteligente con transmisor HART® integrado y tecnología Heartbeat cuenta con el primer sensor RTD del mundo con autocalibración automática in situ. Elimina eficazmente el riesgo de no conformidades no detectadas, reduce el tiempo de inactividad de la producción y aumenta la seguridad de los productos y la eficacia de los procesos en aplicaciones alimentarias, de bebidas y farmacéuticas. El dispositivo cumple plenamente con la norma 21 CFR Parte 11 de la FDA y con la normativa GMP.

Diseñado especialmente para usarse en aplicaciones higiénicas y asépticas en las industrias de alimentación y bebidas y de las ciencias de la vida

Autocalibración RTD en procesos como SIP, UHT, refinado de aceite comestible, fritura industrial de grasa profunda

Rango de medición: de –40 a 190 °C (de –40 a 374 °F)

Clase de protección: IP65/67 o IP69

Salida de señal: 4 a 20 mA, HART®.

Opcional: Secure Bluetooth® y/o WirelessHART® (requiere FieldPort SWA50)

EHEDG, ASME BPE, FDA, 3-A, 1935/2004, 2023/2006, 10/2011, CE, CRN, CSA Propósito general, Protección contra explosiones, por ejemplo, ATEX/IECEx

Ventajas

Reduzca los riesgos y los costes aplicando una autocalibración del sensor RTD en línea totalmente automatizada y trazable. Eliminar las no conformidades o los fallos no detectados

Autocalibración real del sensor RTD sanitario mediante el efecto Curie. Referencia de punto fijo estable a largo plazo incorporada con trazabilidad total de la cadena de calibración al ITS-90

-

Diagnóstico, supervisión y verificación exhaustivos de los instrumentos con Heartbeat Technology

Documentación automatizada del proceso, memoria integrada para 350 eventos de calibración. Acceso 24/7 a certificados de calibración imprimibles y a prueba de auditorías, in situ o a través de la integración del sistema en la nube

Referencia de punto fijo estable a largo plazo incorporada con trazabilidad total de la cadena de calibración a ITS-90

Máxima precisión en la medición de la temperatura. Combinación de transmisor-sensor personalizada en fábrica para obtener la mejor precisión de la RTD

Vídeos

Gama Xpert

-

Productos especializados

- Diseñados para aplicaciones exigentes

Excelencia técnica

Simplicidad

Variable

-

Productos estándar

- Seguros, resistentes y con poco mantenimiento

Excelencia técnica

Simplicidad

-

Productos de alta gama

- Altamente funcionales y prácticos

Excelencia técnica

Simplicidad

-

Productos especializados

- Diseñados para aplicaciones exigentes

Excelencia técnica

Simplicidad

Variable

| Gamas FLEX | Excelencia técnica | Simplicidad |

|---|---|---|

Gama Fundamental Satisfaga sus necesidades básicas de medición |

Excelencia técnica

|

Simplicidad

|

Gama Lean Maneje los principales procesos fácilmente |

Excelencia técnica

|

Simplicidad

|

Gama Extended Optimice sus procesos con tecnologías innovadoras |

Excelencia técnica

|

Simplicidad

|

Gama Xpert Domine las aplicaciones más exigentes |

Excelencia técnica

|

Simplicidad

Variable |

Loading alternative products

Loading alternative products

-

-

Información técnica (TI)

TI iTHERM TrustSens TM371

Versión en español - 10/2022

Sonda compacta de temperatura de tipo métrico para aplicaciones higiénicas y asépticas Comunicación HART

EN ES 31/10/202214/02/202216/06/202114/01/202101/08/2018Idioma:

Español

Versión:

31/10/2022

Tamaño del archivo:

2 MB

Nombre del archivo:

TI01292TES_0822-00.pdf

-

-

-

Información técnica (TI)

TI iTHERM TrustSens TM371

Sonda compacta de temperatura de tipo métrico para aplicaciones

higiénicas y asépticas

Comunicación HARTEN ES 31/10/202214/02/202216/06/202114/01/202101/08/2018Idioma:

Español

Versión:

31/10/2022

Tamaño del archivo:

2 MB

Nombre del archivo:

TI01292TES_0822-00.pdf

-

-

-

Información técnica (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN ES 04/04/202425/03/202415/09/202328/10/202130/07/2021Idioma:

Español

Versión:

04/04/2024

Tamaño del archivo:

1.2 MB

Nombre del archivo:

TI00426FES_2524.pdf

-

-

-

Manual de instrucciones (BA)

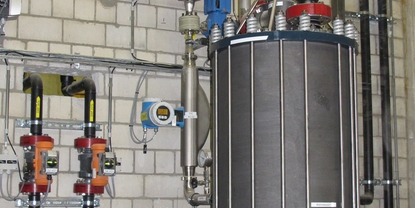

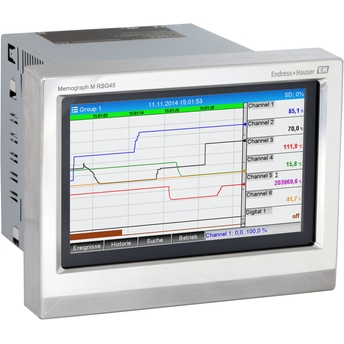

iTHERM TrustSens Calibration Monitoring

Memograph M RSG45 en combinación con iTHERM TrustSens TM37x y el

software Field Data Manager (FDM)EN ES 15/12/202230/11/2018Idioma:

Español

Versión:

15/12/2022

Tamaño del archivo:

2.7 MB

Nombre del archivo:

BA01887RES_0222-00.pdf

-

-

-

Manual de instrucciones (BA)

BA iTHERM TrustSens TM371

Sonda compacta de temperatura de estilo métrico con autocalibración

Comunicación HARTEN ES 31/10/202231/03/202220/01/202121/08/201827/02/2018Idioma:

Español

Versión:

31/10/2022

Tamaño del archivo:

4.3 MB

Nombre del archivo:

BA01581TES_0622-00.pdf

-

-

-

Instrucciones breves (KA)

KA iTHERM TrustSens TM371

Sonda compacta de temperatura con función de autocalibración

Comunicación HART®EN ES 19/01/202331/03/202220/01/202123/02/201820/09/2017Idioma:

Español

Versión:

19/01/2023

Tamaño del archivo:

1.3 MB

Nombre del archivo:

KA01272TES_0523-00.pdf

-

-

-

Instrucciones de seguridad Ex (XA)

CSA Control drawing

CSA Control drawing

Idioma:

Inglés

Versión:

13/05/2022

Tamaño del archivo:

326.3 KB

Nombre del archivo:

XA02869T09_EN.pdf

-

-

-

Instrucciones de seguridad Ex (XA)

iTHERM TrustSens TM371, TM372

Sonda compacta de temperatura de tipo métrico para aplicaciones

higiénicas y asépticas

Comunicación HART®

II1/2G Ex ia IIC T6...T1 Ga/Gb

II1/2D Ех ia IIIC 85 °C…450 °C Da/DbEN ES 07/03/2022Idioma:

Español

Versión:

07/03/2022

Tamaño del archivo:

410.5 KB

Nombre del archivo:

XA02834TES_0122-00.pdf

-

-

-

Documentación especial (SD)

Device viewer

Technical documentation in other languages

Idioma:

Inglés

Versión:

14/07/2021

Tamaño del archivo:

478.5 KB

Nombre del archivo:

SD02429R09EN_0121.pdf

-

-

-

Documentación especial (SD)

SD Hygienic process connection types

Supplement to TM311, TM371, TM372, TM401, TM411, TM402, TM412, TT411,

TT412, TE411, TK40, TMR35, DTT35, TTR35Idioma:

Inglés

Versión:

15/09/2023

Tamaño del archivo:

800.3 KB

Nombre del archivo:

SD03119TEN_0123-00.pdf

-

-

-

PU (publicación)

iTHERM TrustSens Calibration Monitoring - Automated temperature measurement solution

iTHERM TrustSens Calibration Monitoring - Automated temperature

measurement

solution

100% compliance, 0% effort

With automated iTHERM TrustSens calibration monitoring, Endress+Hauser

offers

optimized process verification and higher safety at minimum effort to

users in the

life sciences and food & beverage industries.

The bundle consisting of iTHERM TrustSens TM371 self-calibrating

temperature

sensor, Memograph M RSG45 data manager and FDM Software offers FDA-

compliant process verification, automated, audit-proof documentation and

enables

predictive maintenance.Idioma:

Inglés

Versión:

08/02/2019

Tamaño del archivo:

535.3 KB

Nombre del archivo:

EH_iTHERM_TrustSens_Calibration_Monitoring_PU01310T_EN_0119.pdf

-